Republished with permission from the October 2015 issue of Fourteener Motoring Magazine.

Restoration Design is a one of the Porsche restorer’s most valuable resources. As summer comes to a close, many Porsches come inside to be opened up. Winter is a time of slumber, waiting for the rebirth of spring, and this holds true for many car enthusiasts and their cars.

In the small town of Guelph, Ontario, Restoration Design, Inc, is a company dedicated to supporting the “Porsche Project Car” and its passionate owner. Originally producing parts solely for the Porsche 914, the de Jonge family bought the company in 2009 and has since expanded its product line to include an even wider line of 914 body panels, as well as panels for the 911/912 and the 356.

Restoration Design has made a name for itself due to its obsession with a part’s originality and correctness, by basing all their parts off of original and NOS panels. Working in the opposite direction from Porsche, who generally supersedes parts, Restoration Design has been actively creating the full variance of original factory panels for the discerning restorationist.

Peter de Jonge, one of Restoration Design’s owners, is a Porsche 914 fan, having personally restored his 1973 from the ground up. Being enthusiasts and actual users of their parts has given the de Jonges special help in perfecting their product line and knowing what parts the company should provide to the community next.

The process of actually creating a new part for their product line-up is a complex task that Restoration Design has honed over the years. There are many limitations to getting a piece to market, the first of which being the acquisition of an appropriate NOS panel that can be 3D scanned.

“We have a lot of sources we use to find good original panels,” says Peter, “but often it just comes down to someone knowing us, calling us up, and sending in an old panel they found.”

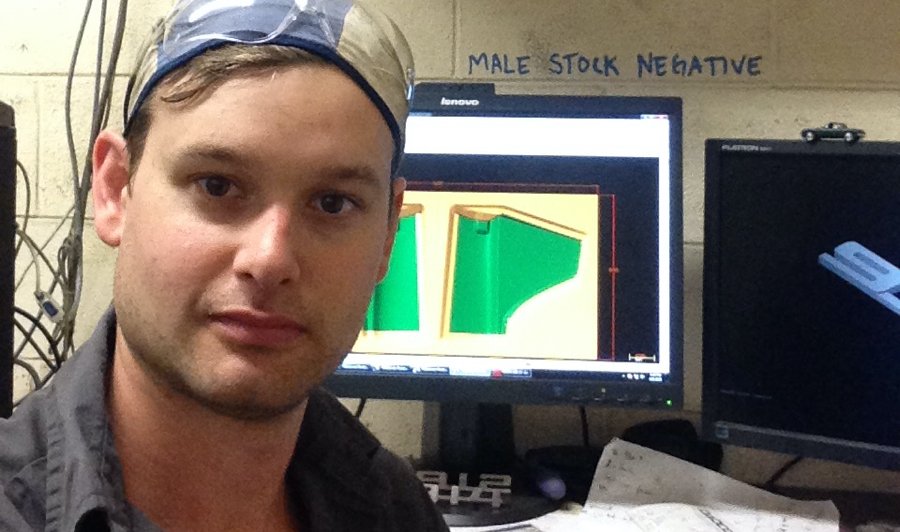

Once a panel is found and scanned, the resulting digital file is fed into one of Restoration Design’s mills. Over the next few weeks, two blank blocks of steel will be slowly milled into two die halves, and then meticulously polished by hand for production by one of the company’s employees. When the die is ready for production, it is loaded into a press and some test pieces are stamped out. If all goes well, the die will stamp out a whole run of panels for sale.

The steel used in these panels is called “galvanneal steel.” It exhibits high anti-corrosion properties, while still being easily paintable. This makes for panels that will last much longer than the original Porsche sheet metal, while still looking perfectly original.

Considering the massive amount of collective effort and work, Restoration Design turns out new parts slowly, albeit consistently. “We have a lot of work to do, even after the part is made,” says Mark Bolton, Restoration Design’s shipping manager, “We’re a small company and we can’t get bogged down with unhappy clients, forcing us to go back and redo dies and products. We have to do it right the first time.”

It is true that customers are generally very satisfied with Restoration Design’s parts. Randy from a local Porsche dismantler and reseller jokingly says that, “if you haven’t heard of Restoration Design, you’re not a real Porsche enthusiast.”

As time goes on, more and more Porsche panels on our cars will be replaced with Canadian parts. Hopefully the next 914 you buy will still have its floors. If not, Restoration Design might be your first call.

Restoration Design

restoration-design.com

519.836.3555

About The Author: Steve

More posts by Steve