Republished with permission from July 2015 issue of Fourteener Motoring Magazine

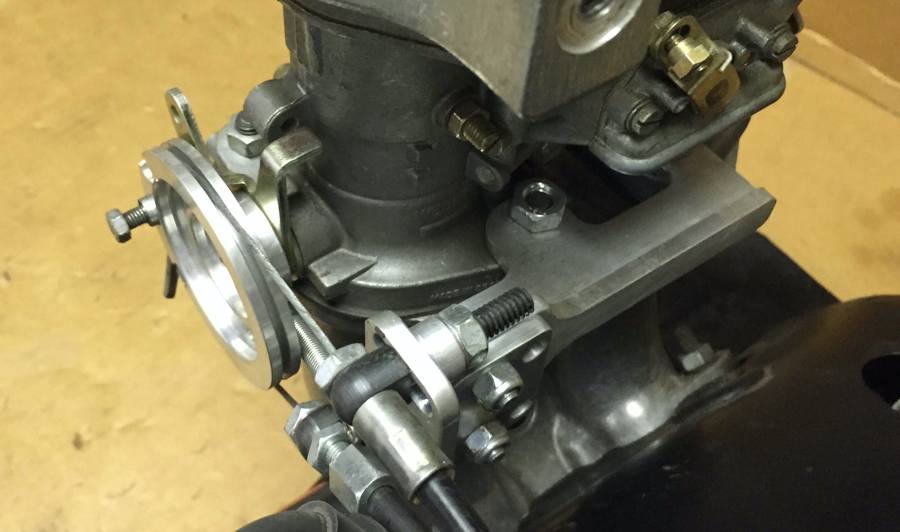

Chris from Tangerine Racing makes some great 914 products, my favorite of which is his pulley linkage for dual carbs. I spent two years fiddling around with my hex bar linkage, but could never get it quite right. If I had it synced at closed throttle, it would be out of sync at wide open and vice versa. I played with the length, angle, and rotation of the hex bar, but I was never happy with the results. I finally decided to buy the Tangerine linkage, and that is my recommendation to anyone running a hex bar set up.

Installation is not too difficult, but there are a few key things to consider before you start.

1) Where do you want the master pulley? The best way to figure this out is to test-mount the cable brackets. If your intake manifolds are short (mine were), the brackets will interfere with the plug wires on number 2 and 4 cylinders, so you need to mount the master pulley towards the rear. If the bracket does not interfere, then I would recommend mounting the master pulley on the front for easier access and adjustment. I ended up putting the master pulley on the passenger side rear. The key idea, besides interference, is making sure you can remove each spark plug for maintenance without trouble.

2) Marking and drilling for the roll pin. Once you know where the master pulley will be, you need to drill a hole in your carb linkage for the roll pin. This pin locks the pulley to the linkage. Chris’ instructions are pretty detailed, but I still had to think this process over. The pulley needs to rotate approximately 90 degrees to fully open the throttle. At wide open throttle, the barrel clamp connecting the throttle cable to the pulley should be at, or just before, it’s highest point. Once you have this figured out, you can determine where to drill. Carb linkage is typically made of very hard metal so make sure you have a good quality drill bit for this step.

3) Minimize the number of bends in the throttle cable when routing it. Per Chris’ recommendation, I drilled a new hole in the tin in the front by the fan, so that I could route the cable up and over the top of the engine. This minimized the bends in the cable, and maximized the usable cable length.

Follow the rest of Chris’ instructions and you should be set. Have someone operate the throttle while you fine-tune the master and slave connections. Make sure that both carbs open at the same time and that they both go to wide open throttle in unison when the gas pedal is pressed to the floor. Remember that there are adjustments in throttle cable length at the front of the tunnel, and that the gas pedal stop is adjustable as well. When you are done, use a snail meter to sync the air flow through the carbs at idle, re-adjust your idle mixture screws and you should be good to go.

Wow!!! I took the car out on the road after set-up and it runs great. Smooth acceleration, and no popping when I let off the gas. My final conclusion… trash your hex bar linkage and install the Tangerine kit. Your improved driving experience awaits you.

About The Author: Steve

More posts by Steve